Oh hey guys, didn't see you there..

This week was quite a blast. But let's recap on what we did last week. Last week, I prepared three concentrations of asphalt concrete:

1.25 g of Asphalt Concrete + 10 mL of toluene

0.0125 g of AC + 10 mL of toluene

0.001025 g of AC + 80 mL of toluene

This week, we decided to compLETELY take out the third dilution because MALDI could not pick up the material, therefore, it can't process it. Fret not, we still got two more dilutions. As you may remember, we placed small parts of the solutions into vials that we took to the new building that has MALDI.

These vials now contain a "matrix," which in this case is CHCA, α-Cyano-4-hydroxycinnamic acid, a powder mixed with toluene.

This week was quite a blast. But let's recap on what we did last week. Last week, I prepared three concentrations of asphalt concrete:

1.25 g of Asphalt Concrete + 10 mL of toluene

0.0125 g of AC + 10 mL of toluene

0.001025 g of AC + 80 mL of toluene

This week, we decided to compLETELY take out the third dilution because MALDI could not pick up the material, therefore, it can't process it. Fret not, we still got two more dilutions. As you may remember, we placed small parts of the solutions into vials that we took to the new building that has MALDI.

|

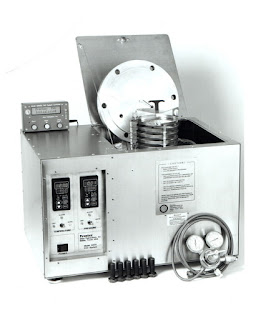

| the new lab |

This matrix is used so that MALDI can analyze the substance, without which it cannot process the material, similar to what happened to the dilution– 0.001025 g AC. The different dilutions are mixed with CHCA matrix, sinapic acid, and 9-Nitroanthracene, and then placed on the plate. This is not described well so I let me illustrate it clearly.

Dilution 1 (1.25 g of AC + 10 mL of toluene) mixed with

1. CHCA

2. Sinapic acid

3. 9-Nitroanthracene

AND

Dilution 2 (0.0125 g of AC + 10 mL of toluene) mixed with

1. CHCA

2. Sinapic acid

3. 9-Nitroanthracene

Then, for the sake of precision and accuracy, each different solution was repeated twice, which occupy around 0.1µL in a small circle on the plate.

A typical result of MALDI looks like this:

As you can see, there are several high peaks reaching high numbers, which signify the component mass. For asphalt concrete, the peaks should be within 200 and 400.

Clearly, this was not the case.

As you probably can't tell through this terribly photographed picture, there are no peaks. There's nothing. So that's research for you. It was kind of a disappointing feeling, BUT this means we have a chance to restart and think about this in a different way. Next week, I will be going more in depth on the physics behind MALDI because frankly, I don't understand it and nothing will make sense until I do.

Photography was my hobby for this week. I explored the new and various types of photography such as nature, portraits, landscape, etc. I also had a lot of fun taking senior pictures!

Anyway, I really don't know if these blogs should have information unrelated to my research, but that's what's going on this week.

Signing off,

Seerat Jajj